Technical Diagnostics

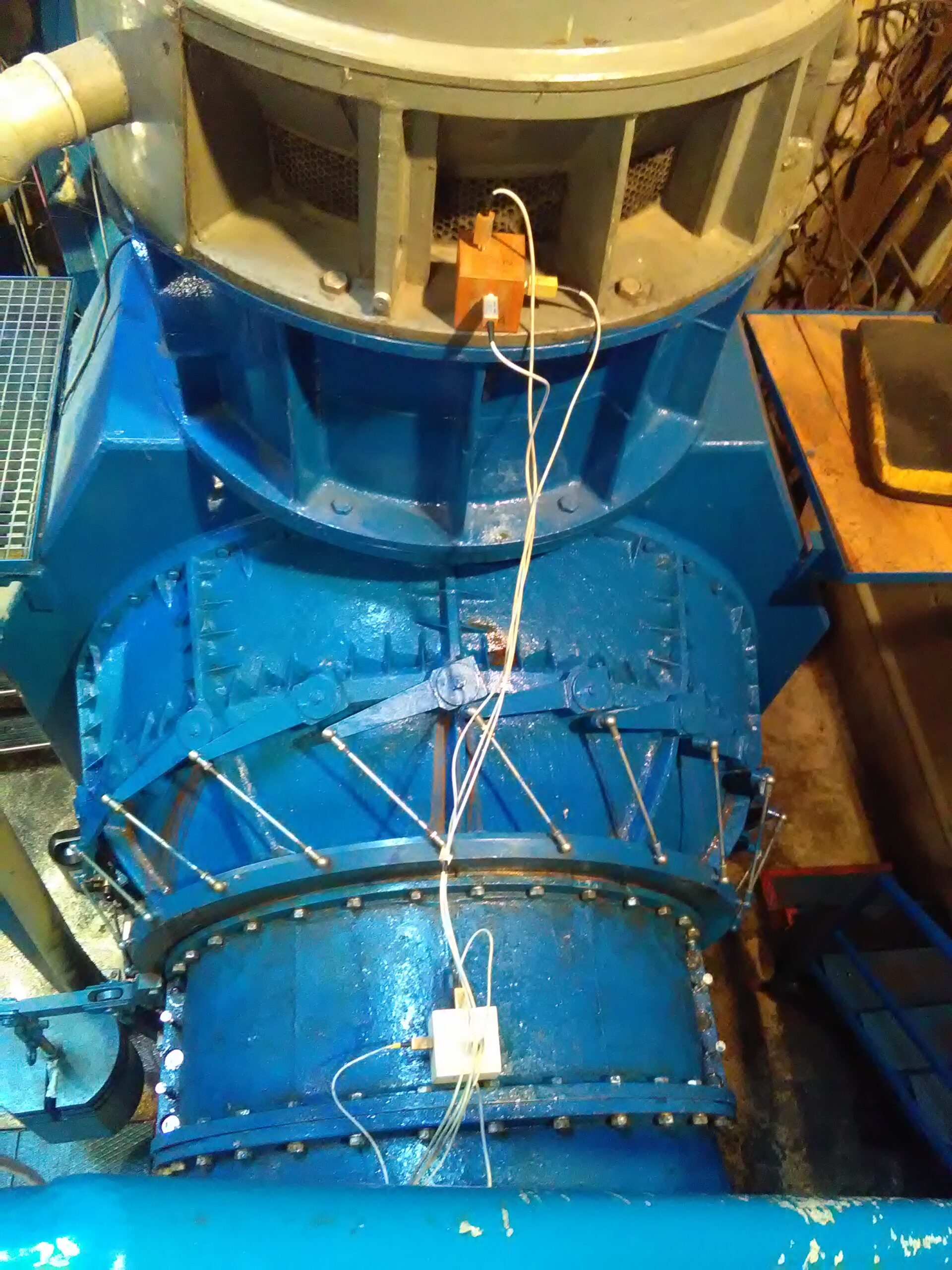

The operation of the technical devices requires the monitoring of their technical condition for the purpose of their monitoring and maintenance planning. The goal is to prevent malfunctions, the elimination of which requires financial costs associated with the unplanned shutdown of the technical device. The magnetic field of the rotating or electrical machines and devices, as well as the magnetization of the ferromagnetic structural elements, are potential sources of information about the state of the given device. By the measurement of these magnetic fields, we can monitor changes over time and detect emerging failure. One of the implemented examples is the measurement of the state of the small hydropower plant with the installed capacity of 400 kW powered by a Kaplan turbine. The advantage of the diagnostics based on the magnetic fields is that it is contactless. The measuring device is placed near the measured device and measures the magnetic field. In comparison to the vibration and tensometric measurements, the preparation of such a measurement is simple and time-saving. After the analyses of the measured data, we were able to confirm the torsional oscillations of the shaft of the Kaplan turbine without the need to shut it down, under the normal operating conditions of the small hydropower plant. To obtain the same result using the tensometric methods, we would have to shut down the turbine, to dismantle its cover and to stick the sensors with the measuring equipment on the shaft, to reassemble the cover and to start the turbine. Saving of costs due to the downtime and manual works is therefore evident.

We wrote in detail about the possibilities of the technical diagnostics in the scientific magazine Sustainability, and you can read it at the following link: https://www.mdpi.com/2071-1050/13/16/9197